De carnívora a vegetariana

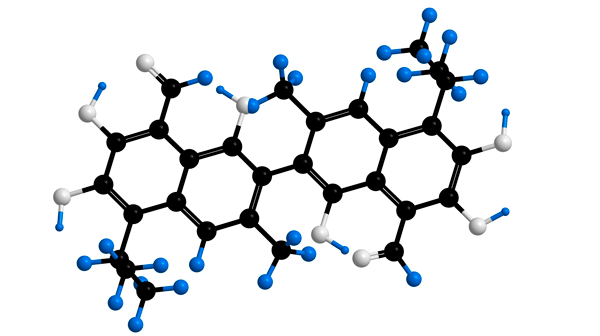

Tradicionalmente a colagenase é uma enzima produzida quando uma bactéria chamada Clostridium histolyticum precisa decompor colágeno, presente em componentes de origem animal, para se alimentar dele.

Pesquisando em solo brasileiro uma cepa da bactéria Clostridium histolyticum, os cientistas do Cristália descobriram e coletaram em Espírito Santo do Pinhal, no interior paulista, uma cepa um pouco diferente. Mimetizaram a presença de colágeno em um meio de cultura vegetal, como se ele de fato estivesse presente. E “enganaram” a bactéria, induzindo-a a produzir colagenase sem colágeno. Assim nasceu a colagenase animal-free do Cristália.

Tecnologia nacional e pureza

A ideia de produzir algo livre de componentes animais vem de várias questões. A principal delas é a conquista de um insumo mais puro, mais ativo e livre de componentes animais, o que significa que a colagenase animal-free poderá ser empregada no isolamento de células-tronco e na Terapia Celular, que requerem o máximo de pureza, uma vez que se tratam de enzimas externas que entram em contato com as células orgânicas.

Adicionalmente, como consequência do feito, pela primeira vez na história o Brasil tem condições de exportar biotecnologia, deixando por completo a necessidade de importar colagenase.

Aprovado!

Por ser animal-free, a aprovação do insumo ocorreu de maneira ágil, uma vez que os órgãos regulatórios, como ANVISA, FDA e EMA valorizam o uso de tecnologias que não usam componentes animais, pois não requerem uma série de comprovações e testes em procedimentos altamente complexos e, consequentemente, demorados.